One of the main issues of the CD555 is the produced heat. Philips added a thick rear plate and the handle for the battery pack represents a kind of a heatsink. Mounted onto this heatsink are the two amplifier ICs and a transistor to generate 15V out of 38V. The difference of 23V will be transformed into heat. In addition the 5V for the CD-Player (decoder and MCU) are generated by a 7805 on the power supply which has to regulate the voltage of about 13V down 5V. This poor little fellow is almost glowing. A nice side effect of my own controller board is, that it uses another supply source to generate the 5V and the 7805 of the CD55 drains less current which helps to reduce the produced heat.

In addition, the original rear plate has absolutely no vent slots and the air flow inside the machine is almost no existing. As a result, the decoder panel with the expensive SAA chipset is getting hot and hotter the longer the machine plays. I lost two controller boards on one machine during the last year due to overheating.

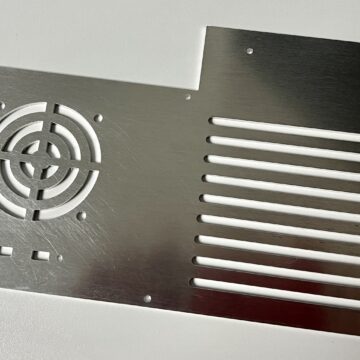

To improve the cooling I designed a new rear plate with vent slots and additional cuttings for a ventilator. It took more than a month to get the laser cut real plate and it was really expensive since there was a minimum order value. Means I had to order 10 cps and got a little bit nervous if everything fits or if I burned the money. Thankfully everything is absolute fine, the plate fits perfectly.

Cleaning takes a long time and afterwards I painted them black to better fits to the machine. I am absolutely happy with the results. An ultra-silent 6cm ventilator shovel fresh air directly onto the CD-decoder SAA chipset which also got some heatsinks for better cooling. Let’s see if we get this thing more stable now…