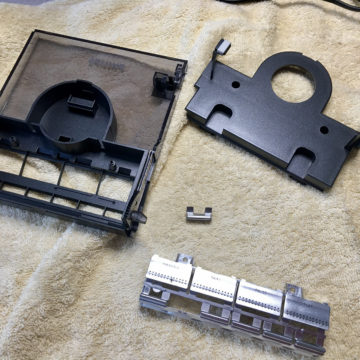

Another problem due to its age are broken keys. Those keys are connected through a very thin piece of plastic which can easily break after more than two decades.

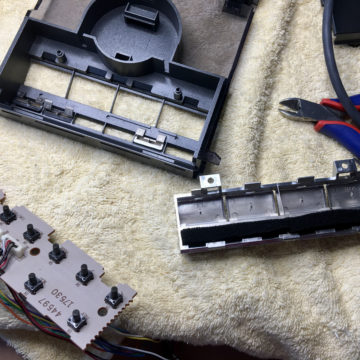

It took me a while to find a way to fix it. The first try was to use some hot glue to put them back in place. It is a little bit flexible to allow to press the button and move back to its original position. Unfortunately this was not working well. Second try included some “self made” springs but I was not satisfied with the results.

To redesign the keyboards and to print it with a 3D printer is a huge amount of work and I am not sure if this will be successful. The procedure also requires a laster printer to put the descriptions onto the keys and I do not have such a device.

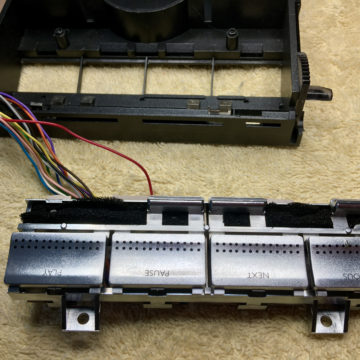

Later on I had an idea to use a sponge from an electronic component package. It is flexible enough to move the button back to its default position and provides a consistent pressure point. The only disadvantage is that the keys can rotate a little bit but I think this can be accepted. It is basically not possible to get any spare parts – except of a working donor.

The solution with the sponge is easy to conduct and of course the possible cheapest way. However, if anyone has any other idea I am eager to get it…