It took a lot of time and patience to repair the tape mechanism. First, the broken lever to switch the servo head between play and fast spinning mode had to be repaired. I tried to glue it but of course it brake again immediately. The problem was that the pin got pressed below the panel with the notch which led to too much tension and broke the pin. Thus it was necessary to figure out why this happened before I replace it and another lever breaks.

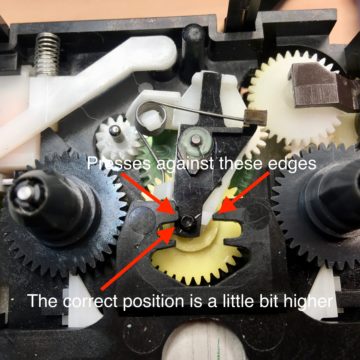

Hard to describe but the issue was that the pin got too close to the notch. Maybe it is getting clear what I mean by the pictures below (think this screams for another YouTube episode). Anyway, to move the default position of the pin a little bit up I used some duck tape on the top side of the lever’s notch.

Well this part got fixed but the tape was still not playing. Of course replacing the belt and removing all the grease that someone put into the mechanism and prevented a smooth run – all did not lead to any success. The electronic worked fine and the pinch rollers are quite new but the best I could get was a stable run on one side but when playing the other side the reel motor drained to much current and the electronic switched off the motor because it thought the tape reached its end.

After hours I ended up using a base plate from another machine and this finally brought the solution. It seems since the thing got repaired so many times the plastic got warped.

In the meantime I found a producer of a gear that possible would work better than my own 3D printed. I am now waiting for them to arrive and to finish the tape deck.

However, there are much more challenges waiting for me with broken keys…